Factory Foundry Metal Silica Sol/Lost Wax-Investment-Precision-Precise-Alloy /Carbon /Metal/Stainless Steel Casting

Features

A variety of different processes are used to manufacture Casting Parts. The process can produce parts that are only a few millimeters thick or as large as five meters. In addition, cast sizes may vary from a few centimetres to over five meters. The size and shape of the part will be determined by the foundry and machining procedures.

Various cast parts require post-production machining. The die used in this process can be either vertical or horizontal. The process is ideal for high-volume production and is cost-efficient for low-volume parts. The only disadvantage of die-casting is that it is not suited for small-scale manufacturing. The size limit of the die for the majority of products is 75 pounds.

The most common types of Casting Parts is die casting. The process is the most affordable for high-volume production runs. Because die casting requires relatively low cost per unit, it is the only process that meets these specifications. However, this process is not suitable for high-pressure applications, and the weight limit of die-casting parts is typically 75 pounds. This process is also not very accurate, so it's not suitable for casting very large components.

Specification

|

item |

steel casting |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-SC002 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer's requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |

LATEST NEWS

Our Craft

Reliable steel casting manufacturer

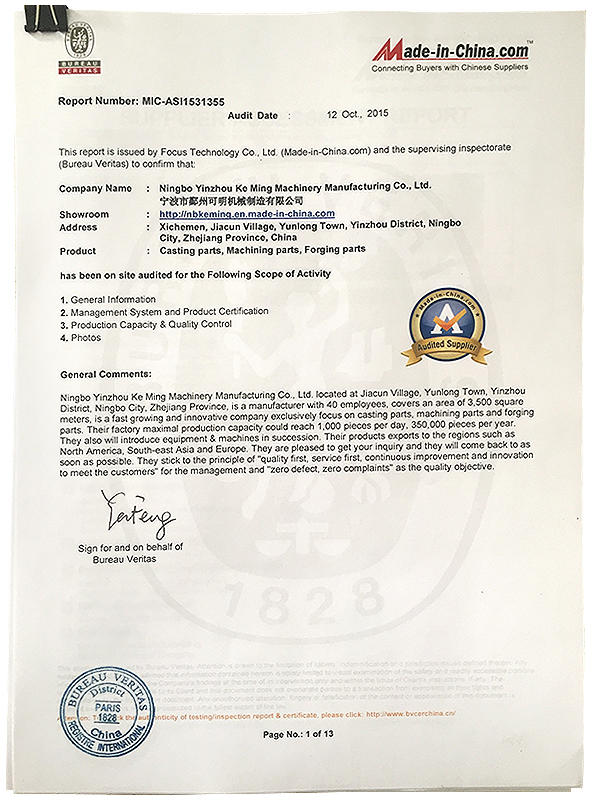

Specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and low alloy steel, is a supplier of investment castings with water glass process in China. We are also leading OEM Factory Foundry Metal Silica Sol/Lost Wax-Investment-Precision-Precise-Alloy /Carbon /Metal/Stainless Steel Casting manufacturers.

It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply both precision castings and finished products with an annual production capacity of over 10000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. We own Advanced foundry that custom Factory Foundry Metal Silica Sol/Lost Wax-Investment-Precision-Precise-Alloy /Carbon /Metal/Stainless Steel Casting.

Our Casting Process >>

-

CASTING

-

HEAT TREATMENT

-

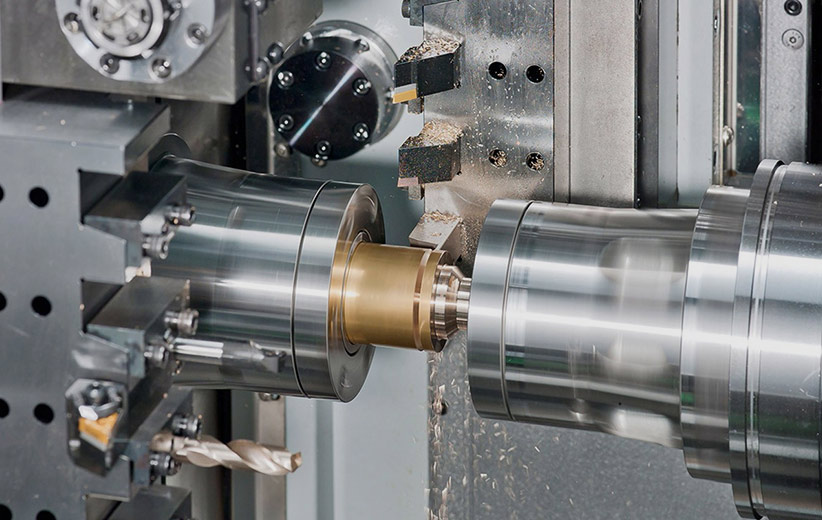

CNC MACHINING

-

PACKAGE

Certified

Contact Us

Related Products

-

Feed port mirror polishing, investment c...

-

Investment/Lost Wax/Precision/Metal Cast...

-

Farm Implements Agricultural Machinery P...

-

Factory Custom Brass Investment Casting ...

-

Cast counterweight model from China

-

Factory High Precise Custom Cast Electr ...

-

China Factory Oem Custom Service Parts S...

-

Factory Custom Metal Alloy Parts Cast St...

-

Customized lost wax casting steel precis...

-

CNC lathes investment castings foundry O...

-

OEM steel lost wax investment cast auto ...

-

Customized Carbon Alloy Speciality Inves...

English

English Español

Español

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.  Phone: +86-13968296962

Phone: +86-13968296962 Fax: +86-0574-88473389

Fax: +86-0574-88473389 Email:

Email: